this is very similar to Quick ‘n dirty DIY Vacuum Feedthrough – Amateur Nuclear Physics

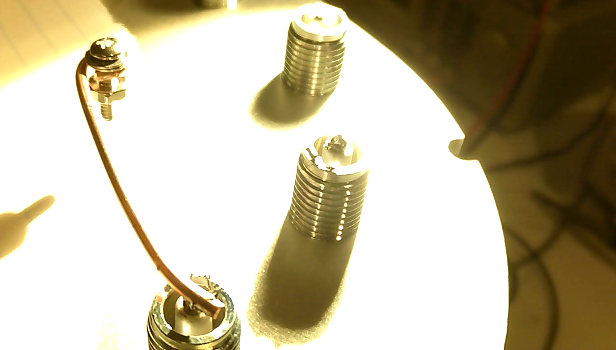

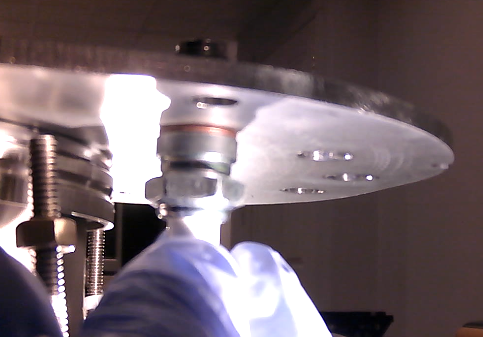

Ordered in some copper crush washers (#97725A250, M12 Screw Size, 12.2 mm ID, 15.9 mm OD, 1.3-1.7 mm thick) from McMaster. These seemed to seal up very nicely. A large amount of torque was required to seat them, and I’m not sure how the aluminum threads are holding up. A substantial amount of black residue was deposited onto the surface of the spark plugs from the last attempts. I am unsure of its composition. I only tested this down to about 2e-5 Torr (2e-3 Pa), probably because the chamber overall was leaky as a sieve.

Ben Krasnow has used spark plugs as well for his SEM, although interestingly he’s flipped them around, with the ceramic on the inside. This might help to prevent virtual leaks around the threads.

In any case, the plug body is typically made of a nickel steel alloy.

Glass tubing for spark plug HV insulation

http://home.earthlink.net/~jimlux/hv/sparkplug.htm

Purchased some NGK D8EA non-resistor gasket copper-core plugs. They’re pretty cheap at $5 to $10 apiece and very readily available. These have an M12 x 1.25 thread and a 3/4" (19 mm) reach, gasket seat, apparently equivalent to Autolite AR4152, NGK D8EA/2120, or Denso X27EP-U9.

Some spark plugs apparently use a talcum powder ring for sealing, but I believe these use a ceramic-to-metal seal.

I cut the existing gaskets off. The vacuum baseplate was about a quarter inch thick. I threaded these with an M12 x 1.25 tap (off Amazon, I think).

I’ve managed to put 45 amps through these plugs for short periods - worked great.

Solder wets the tip of these plugs very well if the surface is sanded slightly. broke the tip off